Daily maintenance of thread rolling machine

Views : 5722

Author : Xiao Yu

Update time : 2020-01-09 18:26:51

Daily maintenance of thread rolling machine

Editor: xiao yu

Why does the thread rolling machine need maintenance?Editor: xiao yu

(1)A frequently-maintained equipment can be used for 10 years or even longer. Conversely, equipment that does not pay attention to maintenance will be easily get damaged, resulting in the new machine becoming an old machine and the old machine becoming a wasted machine. Cost burden for the factory.

(2) If we don’t pay attention of the maintenance,the accuracy of equipment will be quickly lost, resulting in the instability of product precision and defective products. The maintenance of equipment will add extra costs for the enterprise.

(3)With daily maintenance, you can save a lot of time to repair the machine.Spend some times to maintain the machine everyday, the stability of the machine can ensure the delivery time for customers.Like the Chinese old saying goes,Grinding a chopper will not hold up the work of cutting firewood.

How should we maintain the machine?

1:We should listen to the machine for abnormal sounds every day when the machine is turned on. If it is found, check the mechanical parts for looseness. If there is something unusual, we should call a warranty fitter to repair it to avoid the situation from affecting production.

2:We should check whether the oil is sufficient when the machine is turned on every day.Because there is an automatic alarm prompt when the amount of oil is not enough.We can check whether the gearbox or turbine box has sufficient oil lubrication or not. When we find the oil is not enough,we need to add oil. If it is not smooth, we need to dredge. Do not add the wrong oil. We should add the same model and label oil, because each oil has different purposes.

3. Every day,the first rolling workpiece should be compared with the final one made by yesterday.It should be compared to see if the accuracy of the dimension is the same.And the positioning accuracy between heating machine and cooling machine should be the same. All is the same means the machine is normal,otherwise,it's abnormal.

4: Weekly maintenance should be done every week. Operators should perform weekly maintenance strictly in accordance with the maintenance manual under the guidance of management staff.

5. Weekly maintenance should be done every week. Operators should perform weekly maintenance strictly in accordance with the maintenance manual under the guidance of management staff.

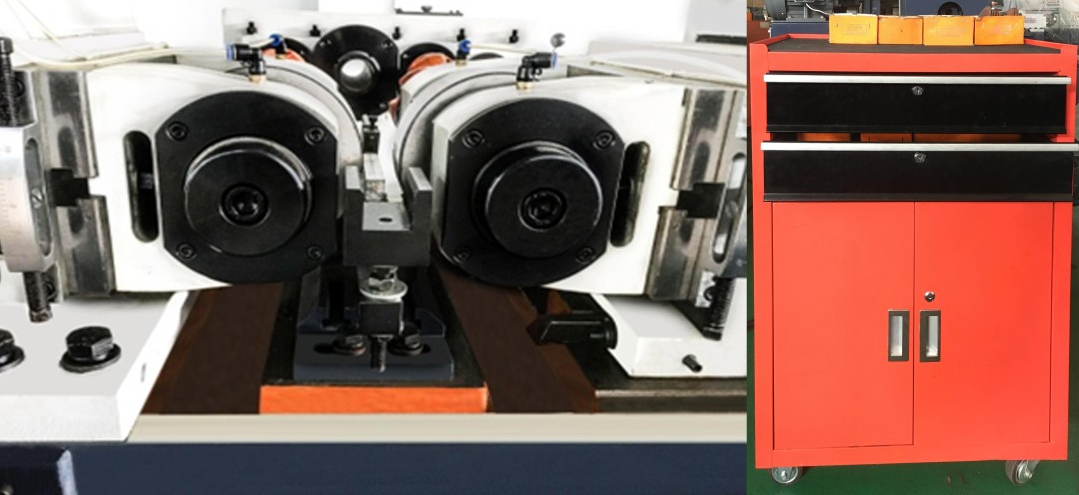

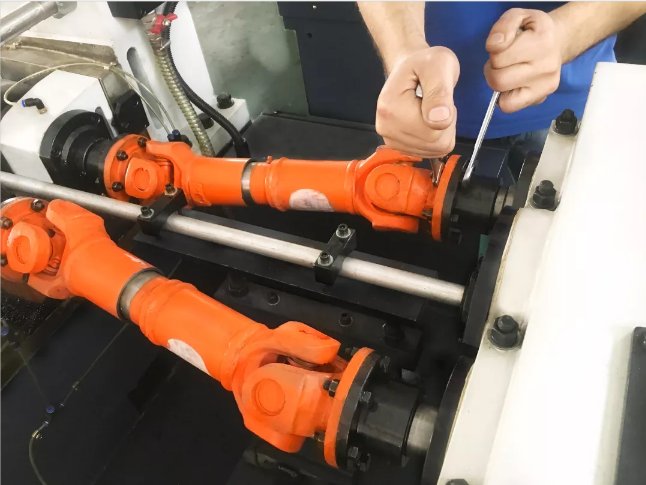

6. Every month, professional technicians should be arranged to perform comprehensive maintenance work on the machine tool, remove the baffle to remove waste residue, clear the oil circuit, replace the oil, check the clearance and lubrication of the universal joint drive shaft, check and adjust the tightness of the machine tool bearings.

The effects on machines with good maintenance

Strengthening the daily maintenance work can not only effectively reduce the equipment failure rate, reduce the maintenance cost, ensure the normal operation of the machine, and improve the economic efficiency of the enterprise, it is of great significance to further improve the equipment management work.

Except above parts, the maintenance of the thread rolling machine may have many details. The maintenance is not perfect. I hope that everyone can learn some problems while learning. The above maintenance part is provided by Shentejia. If you have any questions, just feel free to contact us.

Technical Consultant:Fuxin Hong Technical Reviewer:Yi Lau

Previous :

Features of TOBEST thread rolling machine